I have been working for about 30 years and my personal objective has always been to create more value and to improve the way we work. We spend many hours of our days at work and it can sometimes be a hard, frustrating, stressing, annoying experience. It seems to me that it is worth spending some time and try to make it a “better place” if you spare me the truism.

I have been working for about 30 years and my personal objective has always been to create more value and to improve the way we work. We spend many hours of our days at work and it can sometimes be a hard, frustrating, stressing, annoying experience. It seems to me that it is worth spending some time and try to make it a “better place” if you spare me the truism.

So I have been climbing the work value pyramid (not talking about the hierarchical one, here) and along the way I have met many people traveling the same journey as me. When I talk with these people I often see more or less the same mental model of this chain of increasing value :

Tools > Processes > Methods > Strategy > Culture

The hypothesis is the more you want to gain lever and improve the working organisation, the higher you aim. An hypothesis that doesn’t take into account the fact that soon there are diminishing returns in abstractions as Scott Berkun rightly says. Now that I have been studying and practicing lean for 5 years, I see two missing items in this pyramid while one no longer seems relevant …

Tools, Processes, Methods and Strategy

Let’s start with some descriptions of the different elements of the pyramid.

Tools are what (allegedly) helps team is getting the work done. Nowadays, tools mostly are IT solutions. Think MSOffice, ERP, CRM, CAD, collaboration platforms, PLM, Workflow etc … They often are sold as the silver bullet that will solve the organisation “problems” and, in the worst cases, as the “strategy”. (How many times have I heard that “implementing this ERP is our strategy for the next two years”).

Processes are the encoded different steps of the value chain to create the product or the service. Again, most of the time the processes are built (frozen would be a more appropriate word) into IT solutions. Therefore, processes rely on the tool to help in creating more value for the customer.

Methods are the way people work use Tools and Processes to help in creating value. The example I know best is Agile methodologies using processes (Scrum) and tools (configuration management, continuous integration, visual management, etc …). Yet Agile is a rather advanced model in terms of methodology as it also focusses on software engineering practices with XP (Extreme Programming). This is the part of Agile that is mostly forgotten in massive agile scaling programs, mostly the ones that fail. Unfortunately, Lean management has been considered for a long time as a Management Method with its set of processes and tools. Actually, it sadly still is by many people – including radical management zealot Steve Denning who makes this embarrassing statement in an article about lean.

Lean can be seen as a subset of radical management in the context of manufacturing, just as Scrum and Agile can be seen as subsets of radical management in the context of software development.

Confusing Lean with a management method (or Taiichi forbid, with a subset of radical management for manufacturing) has been the reason why many Lean programs have failed according to Mike Rother and Jeffrey Liker. Denning article being about Liker / Rother paper, it really seems that he hasn’t fully read it.

Strategy is the leaders’ job. It is where the company aims at going. If methods, processes and tools focus on doing the thing right, Strategy aims at doing the right thing (Peter Drucker). A safe bet on how to evaluate a strategy : it is a SMART objective. Example :

- In 10 years, we’ll have a man walking on the moon.

- In 5 years, 50% of our revenues will be from products that are less than 3 years old.

- In 2 years time we’ll have 0 accidents in our factories (this one sounds irrelevant yet you’d be surprised to see the effects of this strategy on the company revenue – a major aluminium player)

Culture

This one is an issue. Don’t get me wrong : people knowing this blog, its subtitle, and the many articles there has been on the topic can hardly blame me on willingly ignoring an essential dimension of organisation dynamics. I fully appreciate the importance of organizational culture. Yet, after all these years, likewise people motivation, I believe you can’t directly act on it using grand scheme actions (town-hall statements, the proverbial values on the wall etc ….).

However, one can definitely take actions that gradually, slowly but surely, change the culture. But this requires a focus on a forgotten item of the pyramid: practices. And more precisely , practice of problem solving. As Edgar Schein explains, organizational culture is :

A pattern of shared basic assumptions learned by a group as it solved its problems of external adaptation and internal integration. A product of joint learning.

Notice how culture is related to problem solving and learning. We’ll get back to this later.

Operations and Practices

This is the first missing item in the above pyramid and interestingly enough it hardly ever is mentioned. It lies at the “lowest” level : Operations. This is the one where the organisation is actually creating value for the customer. The fact that people hardly ever mention it is a good indicator of how much they consider a/the customer b/the people doing the work.

I vividly remember this wake-up call by fellow agilist Charles Couillard who opened my eyes in 2009 : “Come on Cecil : stop it with your culture master plans thing : you can’t act on culture but you can act on your team everyday practices. Change the practices you’ll see the culture change”. This has been an epiphany. A couple of years later while working on this massive project, this is something I have always kept in mind and that has helped me making a dent in the company I was then working for. I have been relentlessly working on daily practices with the actors of this software development R&D team : the team leads, the product owners, the managers, the developers, the testers, UX team etc …

In lean we are obsessional about customer value creation and organisation alignment to create this customer value. As a result, rather than concentrating our efforts on the top layers of the pyramid, we focus on the strategy and then Operations and Practices to understand if the reality of the work being done is aligned with the strategy.

In the new version of the Pyramid, we’ll have Operations and Practices at the first level : this is where the value for the customer is created, this is where the teams are struggling and this were you can directly act on the culture.

Thinking : the missing link

Let us go back to Edgar Schein definition of culture :

A pattern of shared basic assumptions learned by a group as it solved its problems of external adaptation and internal integration. A product of joint learning.

(note : it’s interesting to observe how 3 years later the initial review of this book I highlight completely different parts of this definition).

What Lean really brings to the organisation table is this : proper thinking. This may sound a bit vague and pretentious, yet this is it. Lean is not a set of Methods, Tools etc … it is Thinking. For everybody in the organization. At every stage of the value pyramid. At every level of the hierarchy.

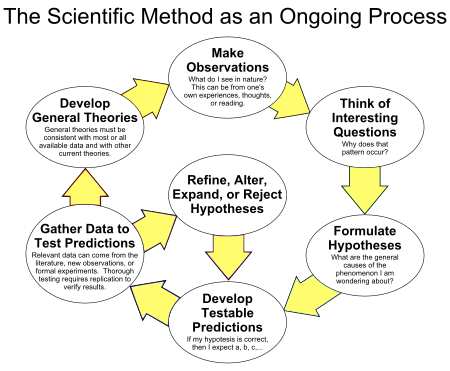

Thinking = Scientific Method

This proper thinking does not come from a new shiny management concept, from silicon valley latest licorn epiphany or from blurry assumptions. It comes from the scientific method develop by Francis Bacon and the Royal Society in the 17th century :

This approach has been translated in the business world by Shewart and Deming with the PDCA cycle : Plan-Do-Check-Act. I understand that in the 21st century it may sound a bit dull and it may seem to lack some excitement and sparkle. Yet, based on 4 centuries of scientific history that has helped in dragging out the world from middle age obscurantism, it will be difficult to deem it as passé and not relevant.

How do you think ?

While walking up the work value chain, I’m afraid we have lost sight on proper thinking – like in scientific approach : observe (where the value is created), define the problem, ask questions to fully investigate the causes, submit hypothesis, test hypothesis, measure the result, validate the learning.

I observe that we often jump to solutions, be it on tools (you need an ERP / CRM / Collaborative Platform … ), processes (workflow, Scrum …), methods (agile, ITIL, community management …) not even making sure what the problem is in the first place.

What scientific method taught us is that we have to ask ourselves questions to make sure we not being carried away by some misconceptions. Thinking is asking ourselves questions. What are the observations our assumptions are based upon ? What is the problem (expecting a measured gap here) ? How will our solution improve the gap ? How do we know ? How do we that we are not self-bullshiting ourselves ? How do we know what we know ?

Coaching into thinking

As Lean coach this is what we do, day in day out : we help people thinking properly using the scientific method. This is why, as a half-joke, I often say that the difference between coaches and consultants is that the latter bring solutions while the former bring questions.

Now it sounds simple yet it is rather difficult – a bit like quitting smoking. It takes discipline, and the worst of all : the discipline of our minds. It requires to be very lucid about the way we think. This is why mindfulness helps a lot and many lean coaches practice it : it helps to keep a step back from the ideas (and the solutions) that run through our mind while facing a situation.

What we aim at is for teams to have both operational practices but also problem solving practices as in the Rother / Like paper.

Thinking to change the culture

Thinking based on problem solving is an essential part of each of the elements of the work pyramid for many reasons.

Firstly it engages everyone in solving problems at their own level to remove obstacles and help the company getting closer to its strategic objectives. Second it makes sure we start with a properly framed problem rather than jump to a solution. Third it allows aligning the whole organisation on the strategy. Fourth, problem solving develops teamwork as people from different functions or department in the organisations will have to work together and solve together a most likely cross-organization problem. Last but not least, this is a major lever to change the culture as culture is developed while solving problems (Schein).

Lean Thinking : stop making sure people don’t think

The problem is that while focussing on tools, processes and methods, organisations have put money and energy on making sure people don’t think. This is what Dan Jones calls designing people out of the process. This has proved not to be as virtuous as initially expected and it is rather surprising from companies who put their people first.

It is time to bring proper thinking to the organisation : this is what Lean has been doing for the last 20 years. As we are celebrating the 20th anniversary of the seminal Lean Thinking book by Womack and Jones, I can’t recommend enough to read it to help organisations to improve their work value pyramid …

The thinking, reverse work value pyramid

… and aim at the the one below :

Notice how this pyramid also provides you with the right order to start your improvement (Kaizen) effort (as per Taiichi Ohno) : the one the closest to where the value is created for the customer.

What is your work value pyramid ?

(click to enlarge)

(click to enlarge)

See also Meadows: 12 points of leverage in a system.